Custom Steel Forgings

Forged Shafts

Quality shaft forgings made of quality steels are ideal shaft blanks for your shafts manufacturing.

Forged Tubes

Forged tubes for hydraulic cylinders and high pressure vessles. 100% high quality with high strength.

Forged Rods

Forged rods can be made of different steels. ESR forged rods also available for you.

Forged Rolls

High quality forged rolls for different hot rolling machines or cold rolling machines. ESR process for long service life.

Forged Wheels

Forged Wheels Forged wheels for cranes, trains and other heavy-duty vehicles.

Forged Disc

H13 H11 Tool steel forgings for different purpose.

Forged Bar

special alloy steel forged round bars are available and can be treated with ESR process.

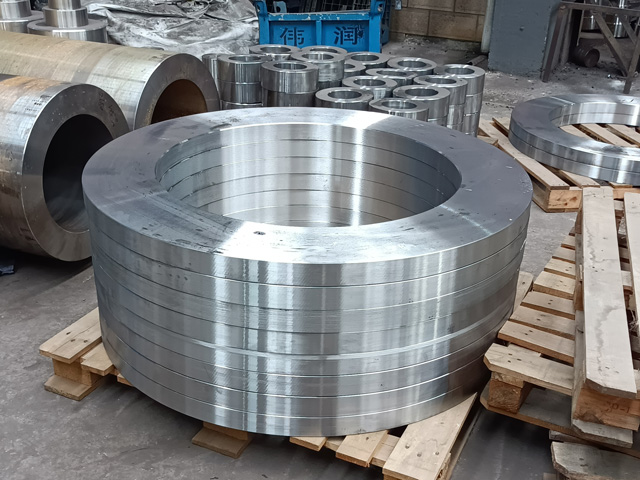

Forged Rings

Hot rolling forging process to get the seamless forged rings. Custom diameters and thickness.