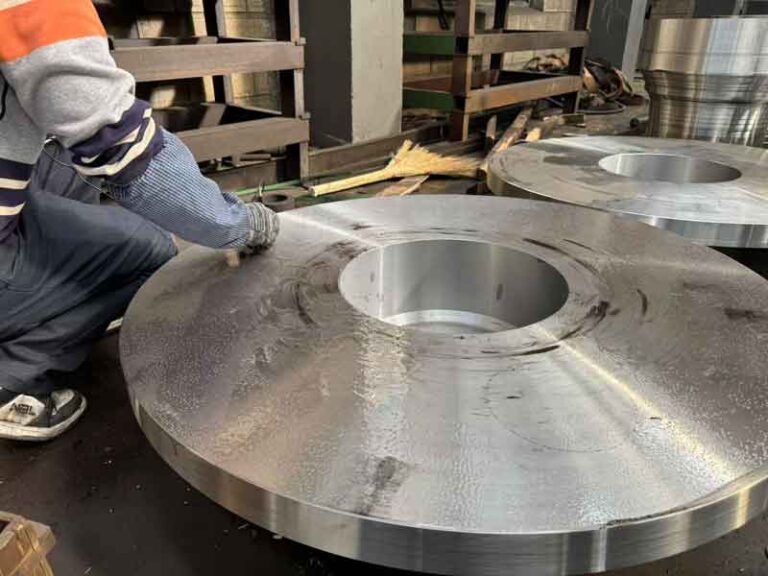

Sleeve Forgings

our sleeve forgings advantages:

- Quick lead time in the industry.

- stainless steel, carbon steel, and alloy steels are available

- Rough machining ensures block forgings size closer to your requirement

- Heat treatment produces block forgings with consistent mechanical properties.

- Testing capabilities to ensure quality and satisfy your requirements

- Ideal for prototypes and short-run situations

Classic tube forgings types:

We manufacture and supply sleeve forgings according to your drawings and requirement. These classic forged sleeves are widely used in different fields.

Deep hole sleeve forgings

Large sleeve forgings

Shaft sleeve forgings

4130 sleeve forgings

Steel forgings materials:

We can supply steel forgings of different materials, such as 4140, 4130, 4340, 17CrNiMo6 etc. Besides these conventional materials, we can also smelt steel according to your chemical composition table. We can also perform electroslag remelting upon request. Our mission is to steel forgings that meet your 100% satisfaction.

Application Industries

Our steel forgings are widely used in wind power industry, chemical industry, machinery industry, automotive industry, marine industry, power plant industry, metallurgy industry, mining industry, petrochemical industry and other industries.

Why Choose Us

To be your best partner for your projects

Profession

We are a professional team to provide products which satisfy your demand.

Cooperation

Mutual benefit and long-term cooperation are our goals.

Service

Professional pre-sales and after-sales service to reduce your cost and save your time.

Quality

Strict with test for production & products and ISO quality management system.