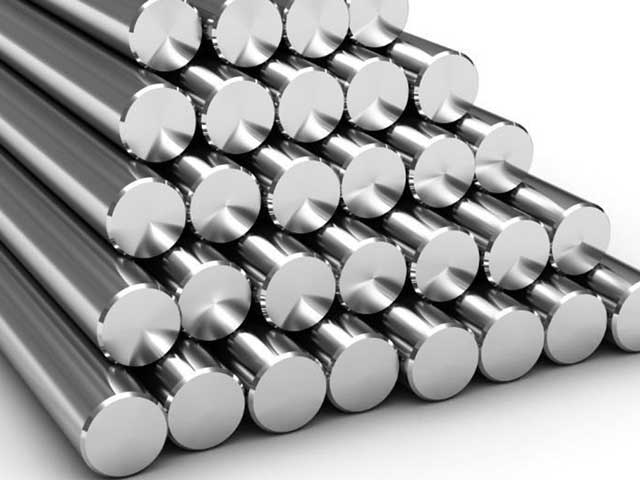

Best stainless steel round bar supplier in China 2021

Stainless steel round bar is one of the most vital players in the machining industry. With the excellent property of corrosion resistance, SS round bar is employed in manufacturing industries that are indulged in the production of fasteners and machinery.

Jiangsu Weirun Forging Co., ltd is a leading SS round bar & rod supplier. We manufacture and supply stainless steel round bar of different grades. We can supply stainless steel round bar with your requested length and diameter.

Our stainless steel round bar is generally supplied in the annealed condition. Some grades such as 17-4 or certain 400 series grades may be hardened by heat-treating. Finishes on bars can vary and include cold drawn, centerless ground, smooth turned, rough turned, turned ground and polished, and HRAP.

Available stainless steel round bar grades

316/316L, 304/304L, 302, 303, 309, 310, 321, 330, 347, 410, 416, 430, 600, 625, 718, 15-5, 17- 4, 17-7, A286, 2205, etc.

We can supply the stainless steel round bar with your requested length

Surface machining services are available

For us, no inquiry is too large or too small. If you do see what stainless steel round bar you are looking for, we would love to assist you and give our quotation! WhatsApp us at +86-183-1708-9408, contact us by email, or simply request a quote. We are your best choice for your current or ongoing projects.

Stainless steel round bar supplier

Jiangsu Weirun Forging Co., Ltd manufactures and tests in strict accordance with international standards and has passed ISO9001 quality management system certification.

The integrity, strength and product quality of Jiangsu Weirun Forging Co., Ltd. have been widely recognized and praised by the industry. We sincerely welcome your visit and inquiry, guide and business negotiation.

Jiangsu Weirun Forging Co., Ltd is mainly engaged in the production and operation of alloy steel smelting, electroslag remelting, forging, casting, mold material production and other projects. After years of development, it has formed a complete industrial chain of material recovery, smelting, electro-slag casting, forging, casting and mold material finishing at home and abroad.

Jiangsu Weirun Forging Co., Ltd. is the professional company specializing in the production and processing of free forging, flange, shaft, reducer accessories, spiral gear, ingot, square billet, continuous casting billet, round billet, round steel and other products, with a complete and scientific quality management system.

Today, the company’s workshops cover more than 60,000 square meters, with 5 sets of 1-ton electro-slag furnaces, 3 sets of 3-ton electro-slag furnaces and 1 set of 10-ton electro-slag furnace; Two sets of 2-ton air hammers, one set of 1-ton air hammer, one set of 0.75-ton air hammer, one set of 3-ton fully mechanized electro-hydraulic hammer production line, one 8-ton fully mechanized electro-hydraulic hammer production line and one casting production line. It has complete machining equipment, heat treatment equipment, spectrum analyzer and various physical and chemical performance testing equipment.

Company View

Forging is to exert external pressure on the metal blank to make the metal blank produce plastic deformation and change the mechanical properties of the metal blank. Through forging, metal porosity and holes can be eliminated. So as to improve the mechanical properties of metal. With excellent quality and reasonable price, our forgings have been widely used.

- Steve Wei Sales Manager

- +86-183-1708-9408

- +86-183-1708-9408

- +86-0511-86360978

- steve@well-forge.com